Vehicle scales are specialized devices designed to measure the weight of vehicles, typically trucks or other heavy-duty transports. They play a crucial role in various industries where accurate weight measurement is essential for legal, safety, and logistical reasons. Therefore, choosing the right scale solutions and providers and navigating the regulatory environment are necessary to ensure a seamless operation.

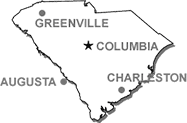

When searching for “vehicle scales near me,” Carolina Scales is your go-to provider of reliable and innovative weighing solutions in North and South Carolina and Georgia. We offer a comprehensive range of industrial scales to cater to the varied needs of our clientele.

Types of Vehicle Scales in North Carolina, South Carolina and Georgia

There are various kinds of vehicle scales, each designed to serve specific purposes and industries. Here are some of the types you will find when you search “vehicle scales near me”:

-

Weighbridges

Weighbridges are large, stationary scales designed to weigh entire vehicles. They consist of a flat platform supported by load cells, which measure the vehicle's weight when it drives onto the platform. These are commonly used in transportation, logistics, and industries where accurate weight measurement of entire vehicles is crucial for legal compliance and operational efficiency.

-

Portable Scales

A portable or mobile scale is smaller and more flexible than weighbridges. It can be easily transported and set up in different locations for temporary weighing needs. This type is often used in agriculture, construction, and waste management industries, where the ability to measure vehicle weights on the go is essential.

-

Axle Scales

Axle scales are designed to measure the weight of individual vehicle axles. They consist of separate platforms positioned under a specific axle, allowing for accurate weight measurements. These are crucial for industries that require compliance with axle weight regulations, such as transportation and logistics.

-

In-Ground Scales

An in-ground vehicle scale is installed flush with the ground, providing a surface level with the surrounding area. The weighing components are typically embedded in a pit beneath the scale surface, offering a seamless and durable solution for weighing heavy loads. It is commonly used in industries where a level surface is crucial, such as mining, agriculture, and heavy-duty manufacturing.

-

Onboard Weighing Systems

An onboard weighing system directly integrates into the vehicle, providing real-time weight measurements. These systems often include sensors and displays within the vehicle cabin. Onboard systems are commonly used in waste management, agriculture, and transportation, as they require frequent and immediate weight data.

-

Rail Scales

A rail scale is specifically designed for weighing rail cars and their contents. It can be installed along railway tracks, allowing for accurate weight measurement as trains pass over them. Rail scales are particularly essential for precise measurement of transported goods in industries like mining, agriculture, and manufacturing.

-

Intermodal Scales

Intermodal scales are used to weigh shipping containers. They can be integrated into transportation hubs or container yards to ensure that containers meet weight regulations for safe transportation. This type is essential in the shipping and logistics industry, helping to prevent overloading and ensuring compliance with international container weight standards.

Choosing the Right Vehicle Scales Provider

Partnering with the right supplier can impact your operations’ efficiency, compliance, and success. When you look up “vehicle scales near me,” remember to consider these factors in selecting a provider:

- Industry experience: A provider with an extensive background often carries more knowledge of diverse scales and local regulations. They are also more likely to know how to address specific challenges.

- Product range and technology: Choose a supplier that provides a range of products, from traditional weighbridges to more advanced solutions. Consider whether their technology aligns with industry standards and your operational requirements.

- Local expertise: Opt for a business with local expertise, especially if your operations are concentrated in specific regions like North and South Carolina and Georgia. Their local knowledge helps navigate regional regulations and ensures a quicker response to your needs.

- Comprehensive services: The ideal partner will be well-equipped to cover all your industrial weighing needs, from installation and calibration to maintenance and repairs.

- Reputation: Research the supplier’s reputation by checking reviews, testimonials, and references. A company with positive feedback and a strong reputation will likely deliver reliable services and high-quality products.

- Scalability: Choose a partner that can accommodate your current needs but also has the flexibility to scale as your business grows. Consider whether they can support additional scales, integrate new technologies, and adapt to changing requirements.

- Product quality: Assess the quality of the scales the provider offers. High-quality vehicle scales from well-known brands are more likely to be accurate, durable, and low-maintenance.

- Cost: It is important to prioritize value for money over the lowest price. Consider the overall cost of ownership, including installation, maintenance, and potential downtime. A slightly higher upfront cost may be justified by long-term reliability and performance.

- Warranty and service contracts: Review the warranty terms for the scales and inquire about available service contracts. Understanding the coverage and duration of warranties helps you anticipate potential costs and ensures ongoing support.

Tips To Navigating Local Regulations in North and South Carolina and Georgia

Understanding local regulations is crucial when installing and using vehicle scales. In North and South Carolina and Georgia, specific rules govern the use of scales to ensure fair trade, road safety, and compliance with legal standards. Here are essential tips to help you navigate these regulations:

1 Understand State-Specific Laws

Knowing the legal framework is the first step towards compliance. Familiarize yourself with the state-specific rules governing weights and measures in North and South Carolina and Georgia. In North Carolina, you can refer to the 2022 North Carolina General Statutes – Article 3, Chapter 20, § 20-118 for details. Meanwhile, South Carolina, the Code of Laws – Title 56, Chapter 5, outlines these regulations. On the other hand, Georgia’s laws are detailed in O.C.G.A. – Title 32, Chapter 6, Article 2.

2 Know Vehicle Weight Limits

North and South Carolina and Georgia impose specific limits on gross vehicle and axle weights to ensure road safety and prevent damage to infrastructure. Regularly check and monitor these limits to avoid violations.

3 Regularly Inspect and Calibrate Scales

Both North and South Carolina, as well as Georgia, require regular inspections of vehicle scales to ensure accuracy. Create an inspection schedule and work with a reliable service provider who understands local regulations. Regular calibration is also essential to maintain accurate measurements and compliance.

4 Maintain Detailed Records

Keep comprehensive records of scale inspections, calibrations, and any maintenance activities. Accurate record-keeping is a regulatory requirement and serves as documentation during inspections, demonstrating your commitment to compliance.

5 Collaborate With Reputable Service Providers

Choose service providers like Carolina Scales, with a proven track record of expertise in the North and South Carolina and Georgia markets. Professional supplies ensure the quality of your scales while assisting with compliance-related services, including inspections and maintenance.

6 Stay Proactive and Engage in Training

Stay updated with the industry news, attend training sessions, and educate your staff on the latest regulations. Staying informed and ensuring that your team understands compliance requirements contributes to a culture of accountability within your organization.

7 Regularly Review and Update Compliance Strategies

As local regulations evolve, it is essential to regularly review your compliance initiatives. Stay informed about legislative changes and adjust your practices to ensure ongoing adherence.