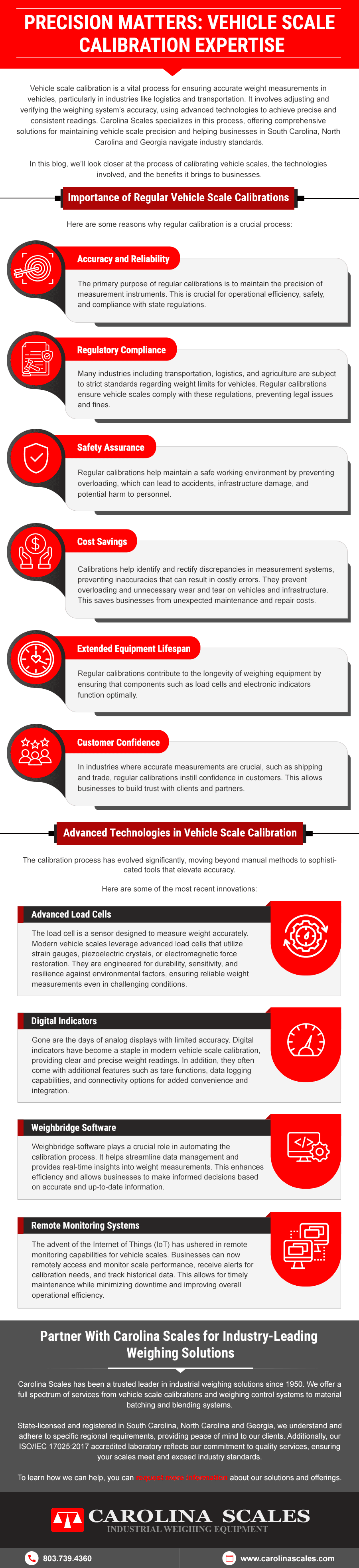

Vehicle scale calibration is a vital process for ensuring accurate weight measurements in vehicles, particularly in industries like logistics and transportation. It involves adjusting and verifying the weighing system’s accuracy, using advanced technologies to achieve precise and consistent readings. Carolina Scales specializes in this process, offering comprehensive solutions for maintaining vehicle scale precision and helping businesses in South Carolina, North Carolina and Georgia navigate industry standards.

In this blog, we’ll look closer at the process of calibrating vehicle scales, the technologies involved, and the benefits it brings to businesses.

Importance of Regular Vehicle Scale Calibrations

Here are some reasons why regular calibration is a crucial process:

- Accuracy and reliability: The primary purpose of regular calibrations is to maintain the precision of measurement instruments. This is crucial for operational efficiency, safety, and compliance with state regulations.

- Regulatory compliance: Many industries including transportation, logistics, and agriculture are subject to strict standards regarding weight limits for vehicles. Regular calibrations ensure vehicle scales comply with these regulations, preventing legal issues and fines.

- Safety assurance: Regular calibrations help maintain a safe working environment by preventing overloading, which can lead to accidents, infrastructure damage, and potential harm to personnel.

- Cost savings: Calibrations help identify and rectify discrepancies in measurement systems, preventing inaccuracies that can result in costly errors. They prevent overloading and unnecessary wear and tear on vehicles and infrastructure. This saves businesses from unexpected maintenance and repair costs.

- Extended equipment lifespan: Regular calibrations contribute to the longevity of weighing equipment by ensuring that components such as load cells and electronic indicators function optimally.

- Customer confidence: In industries where accurate measurements are crucial, such as shipping and trade, regular calibrations instill confidence in customers. This allows businesses to build trust with clients and partners.

Advanced Technologies in Vehicle Scale Calibration

The calibration process has evolved significantly, moving beyond manual methods to sophisticated tools that elevate accuracy. Here are some of the most recent innovations:

1. Advanced Load Cells

The load cell is a sensor designed to measure weight accurately. Modern vehicle scales leverage advanced load cells that utilize strain gauges, piezoelectric crystals, or electromagnetic force restoration. They are engineered for durability, sensitivity, and resilience against environmental factors, ensuring reliable weight measurements even in challenging conditions.

2. Digital Indicators

Gone are the days of analog displays with limited accuracy. Digital indicators have become a staple in modern vehicle scale calibration, providing clear and precise weight readings. In addition, they often come with additional features such as tare functions, data logging capabilities, and connectivity options for added convenience and integration.

3. Weighbridge Software

Weighbridge software plays a crucial role in automating the calibration process. It helps streamline data management and provides real-time insights into weight measurements. This enhances efficiency and allows businesses to make informed decisions based on accurate and up-to-date information.

4. Remote Monitoring Systems

The advent of the Internet of Things (IoT) has ushered in remote monitoring capabilities for vehicle scales. Businesses can now remotely access and monitor scale performance, receive alerts for calibration needs, and track historical data. This allows for timely maintenance while minimizing downtime and improving overall operational efficiency.

Partner With Carolina Scales for Industry-Leading Weighing Solutions

Carolina Scales has been a trusted leader in industrial weighing solutions since 1950. We offer a full spectrum of services from vehicle scale calibrations and weighing control systems to material batching and blending systems.

State-licensed and registered in South Carolina, North Carolina and Georgia, we understand and adhere to specific regional requirements, providing peace of mind to our clients. Additionally, our ISO/IEC 17025:2017 accredited laboratory reflects our commitment to quality services, ensuring your scales meet and exceed industry standards.

To learn how we can help, you can request more information about our solutions and offerings.