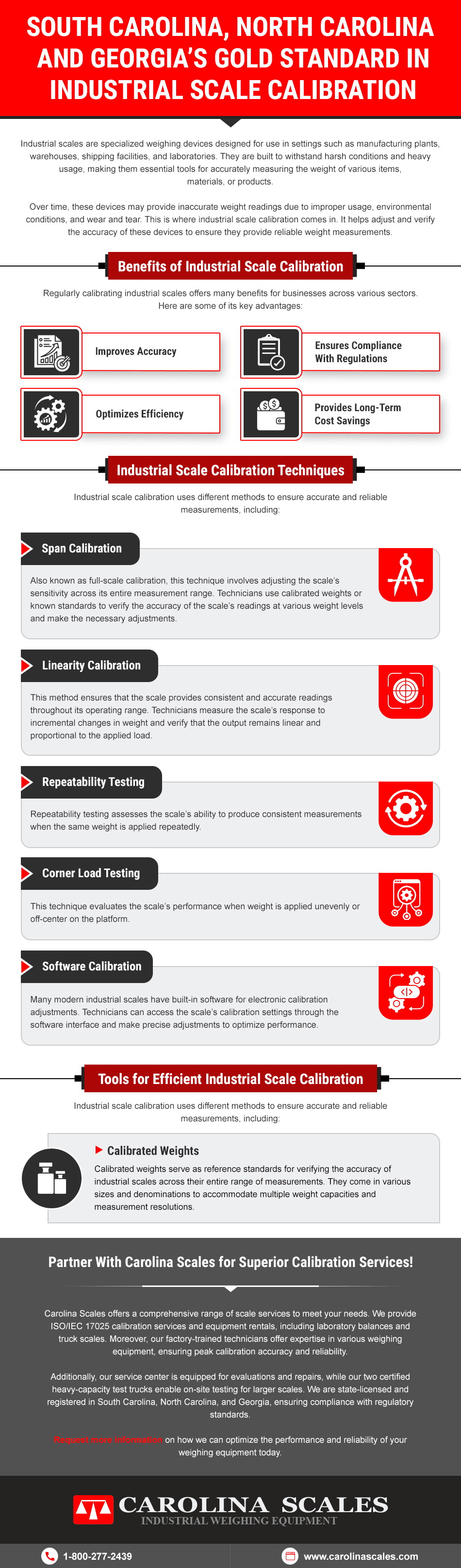

Industrial scales are specialized weighing devices designed for use in settings such as manufacturing plants, warehouses, shipping facilities, and laboratories. They are built to withstand harsh conditions and heavy usage, making them essential tools for accurately measuring the weight of various items, materials, or products.

Over time, these devices may provide inaccurate weight readings due to improper usage, environmental conditions, and wear and tear. This is where industrial scale calibration comes in. It helps adjust and verify the accuracy of these devices to ensure they provide reliable weight measurements.

In this article, we will look at the significance of regular calibration and the different techniques and tools involved.

Benefits of Industrial Scale Calibration

Regularly calibrating industrial scales offers many benefits for businesses across various sectors. Here are some of its key advantages:

Improves Accuracy

Calibration ensures that industrial scales provide precise and reliable measurements. This is crucial for maintaining quality control, ensuring product consistency, and avoiding errors in processes such as manufacturing, packaging, and shipping.

Ensures Compliance With Regulations

Expert industrial scale calibration helps businesses comply with regulatory standards by ensuring their devices meet the required standards. In addition, regular documentation of calibration activities demonstrates a commitment to quality, reducing the risk of fines, penalties, or legal issues and enhancing overall operational efficiency.

Optimizes Efficiency

Industrial scale calibration helps businesses correct any inaccuracies or inconsistencies in their weighing equipment. This enables smoother operations and minimizes disruptions caused by errors or discrepancies.

Provides Long-Term Cost Savings

While investing in regular calibration may incur upfront costs, the long-term benefits far outweigh the expenses. By preventing errors, minimizing rework, and optimizing processes, calibrated scales help businesses save money in the long run. Moreover, timely calibration can extend the lifespan of industrial scales by detecting and addressing issues early, reducing the need for costly repairs or replacements.

Industrial Scale Calibration Techniques

Industrial scale calibration uses different methods to ensure accurate and reliable measurements, including:

- Span calibration: Also known as full-scale calibration, this technique involves adjusting the scale’s sensitivity across its entire measurement range. Technicians use calibrated weights or known standards to verify the accuracy of the scale’s readings at various weight levels and make the necessary adjustments.

- Linearity calibration: This method ensures that the scale provides consistent and accurate readings throughout its operating range. Technicians measure the scale’s response to incremental changes in weight and verify that the output remains linear and proportional to the applied load.

- Repeatability testing: Repeatability testing assesses the scale’s ability to produce consistent measurements when the same weight is applied repeatedly.

- Corner load testing: This technique evaluates the scale’s performance when weight is applied unevenly or off-center on the platform.

- Temperature compensation: Temperature compensation techniques adjust the scale’s calibration to account for temperature variations, ensuring accurate measurements regardless of environmental conditions.

- Software calibration: Many modern industrial scales have built-in software for electronic calibration adjustments. Technicians can access the scale’s calibration settings through the software interface and make precise adjustments to optimize performance.

Tools for Efficient Industrial Scale Calibration

Technicians use specialized tools to ensure accurate and reliable calibration of industrial scales. These include:

- Calibrated weights: Calibrated weights serve as reference standards for verifying the accuracy of industrial scales across their entire range of measurements. They come in various sizes and denominations to accommodate multiple weight capacities and measurement resolutions.

- Force gauges: These instruments measure the force applied to a scale’s platform. They may be mechanical or digital and are available in various configurations to accommodate different scales and weighing applications.

- Torque wrenches: Torque wrenches tighten and adjust the fasteners and components of industrial scales, such as load cells, mounting hardware, and structural supports.

- Leveling tools: Bubble, digital, and laser levels ensure that the scale’s platform is parallel to the ground and free from any inclination that could affect its performance.

Partner With Carolina Scales for Superior Calibration Services!

Carolina Scales offers a comprehensive range of scale services to meet your needs. We provide ISO/IEC 17025 calibration services and equipment rentals, including laboratory balances and truck scales. Moreover, our factory-trained technicians offer expertise in various weighing equipment, ensuring peak calibration accuracy and reliability.

Additionally, our service center is equipped for evaluations and repairs, while our two certified heavy-capacity test trucks enable on-site testing for larger scales. We are state-licensed and registered in South Carolina, North Carolina, and Georgia, ensuring compliance with regulatory standards.

Request more information on how we can optimize the performance and reliability of your weighing equipment today.