Keeping You on Track: South and North Carolina and Georgia’s Best in Vehicle Scale Repairs, Rebuild, and Refurbish

Leave a CommentVehicle scales or weighbridges are large weighing platforms supported by load cells or strain gauges. When a vehicle drives onto the scale, its weight is measured and displayed on an indicator or sent to a computer system for analysis. These scales ensure compliance with weight regulations while helping calculate shipping costs and monitor inventory levels.

Like any other equipment, these scales require maintenance and occasional refurbishments to operate at their best. This article explores the importance of keeping up with regular vehicle scale repairs and upkeep and how Carolina Scales can help.

Why Do You Need Vehicle Scale Repairs, Rebuild, and Refurbish Services?

Here are several reasons why maintaining and servicing vehicle scales is essential:

1. Accuracy and Precision

Any inaccuracies in weight measurements can lead to costly errors, such as undercharging or overcharging customers, inventory mismanagement, or non-compliance with weight regulations. Regular repairs, rebuilds, and refurbishments ensure that vehicle scales maintain accuracy and precision, minimizing the risk of errors and optimizing operational efficiency.

2. Regulatory Compliance

Many industries are subject to strict regulations regarding weight limits for vehicles transporting goods on public roads. Overloaded vehicles pose safety risks and may incur hefty fines and penalties for non-compliance. Properly maintained and calibrated scales ensure that vehicles remain within legal weight limits and help businesses avoid regulatory violations.

3. Extended Lifespan

Vehicle scales require regular maintenance to prevent wear and tear and ensure longevity. Repairs and refurbishments address issues such as damaged load cells, worn-out components, or corrosion, reducing problems and premature failure of the scale.

4. Minimized Downtime

Downtime due to scale malfunctions can disrupt operations and result in reduced productivity. Proactive maintenance practices — such as scheduled inspections and preventive vehicle scale repairs — can identify potential issues early on, ensuring continuity of operations and customer satisfaction.

5. Cost Savings

Maintaining optimal performance and accuracy of vehicle scales helps businesses avoid costly errors, regulatory fines, and downtime-related losses. Furthermore, extending the lifespan of equipment through regular maintenance can delay the need for expensive replacements, ultimately reducing overall operating costs and improving profitability.

Carolina Scales: South and North Carolina’s Leading Solution

When it comes to vehicle scale repairs, rebuilds, and refurbishments in South and North Carolina, Carolina Scales stands out as a trusted provider across industries. We are your go-to destination for all vehicle scale needs, setting the standard for delivering top-notch services.

Here are the guarantees you will receive when you work with us:

Unmatched Expertise

Carolina Scales boasts a team of factory-trained technicians with years of experience and a full understanding of the intricacies of various vehicle scales. From traditional mechanical scales to the latest digital ones, we have the knowledge and expertise to handle them all.

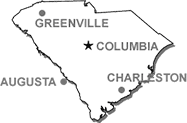

Accredited and Licensed

We pride ourselves on upholding the highest standards of quality and professionalism. Our laboratory is accredited to the ISO/IEC 17025:2017 standard, ensuring our services meet industry benchmarks. Furthermore, the company is state-licensed and registered in South Carolina, North Carolina, and Georgia. This ensures that your operations adhere to stringent regulatory requirements and industry best practices.

Round-the-Clock Support

Our dedicated team of technicians is available 24/7 to promptly address your vehicle scale repairs and maintenance needs. With fully stocked replacement parts and the necessary tools, we guarantee a swift emergency response time of within three hours, day or night.

Transparency and Accountability

Carolina Scales offers a Certificate Retrieval System (CRS) to streamline the calibration process and enhance transparency. It allows clients to access calibration certificates from a secure website, providing visibility into the servicing history of their weighing equipment. This ensures that every calibration test is meticulously documented, giving peace of mind and assurance of accuracy.

Carolina Scales: Your Trusted Partner for Precision Weighing Solutions and Services

At Carolina Scales, we pride ourselves on delivering a superior service that exceeds expectations. With our team of expert technicians boasting decades of collective experience, we guarantee top-notch vehicle scale repair, refurbishment, and rebuilding services. We also offer a wide selection of vehicle scales from industry-leading manufacturers, ensuring you have access to the best equipment on the market.

In addition to our extensive product offerings, we also provide flexible rental options for businesses needing temporary weighing solutions. Request more information on our product offerings, rental options, and personalized solutions tailored to your business needs!